The development of long-life, non-polluting molten steel, which can reduce the inclusions and harmful elements in steel and its application technology is an important task to meet the production of clean steel. The project proposes a technical route for the carbon-free longevity of ladle lining, the all-alkaliization of tundish lining and the optimization of structure and parameters of functional refractory for refining. The performance and application effect of carbon-free long-life ladle lining materials developed and surpassed that of Japan and Austria. The performance and level of use of the anti-pollution tundish lining material is comparable to that of similar materials in Japan and the United States.

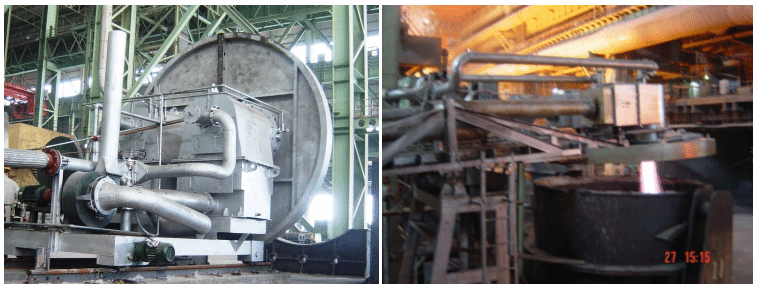

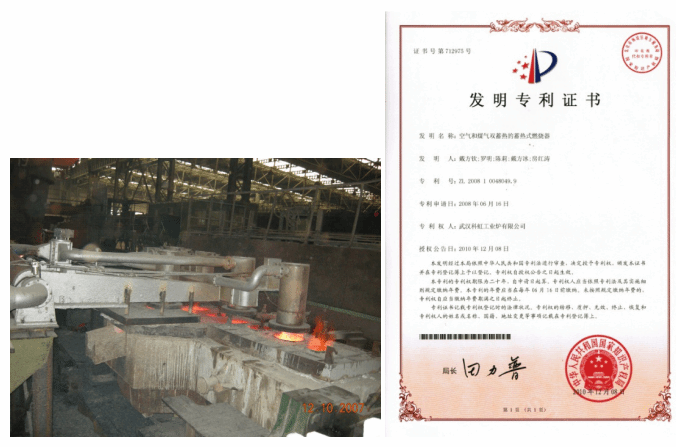

Regenerative combustion technology, also known as high-temperature air combustion technology, can maximize the recovery of high-temperature flue gas waste heat and improve the thermal efficiency of energy-using equipment. The project was jointly developed by Professor Dai Fangqin and Wuhan Kehong Industrial Furnace Co., Ltd., and undertook the “Technology Development of Energy-efficient and Environmentally-friendly Regenerative Forge Heating Furnace” of Wuhan 2010 Science and Technology Plan Project. There are 2 patents for "regenerative burners with double heat storage for air and gas" and "regenerative burners for air single heat storage". At present, the technology has been applied to ladle baking, tundish baking, ladle baking, forging heating furnace, heat treatment furnace and aluminum melting furnace in steel plants, and has achieved good economic benefits.