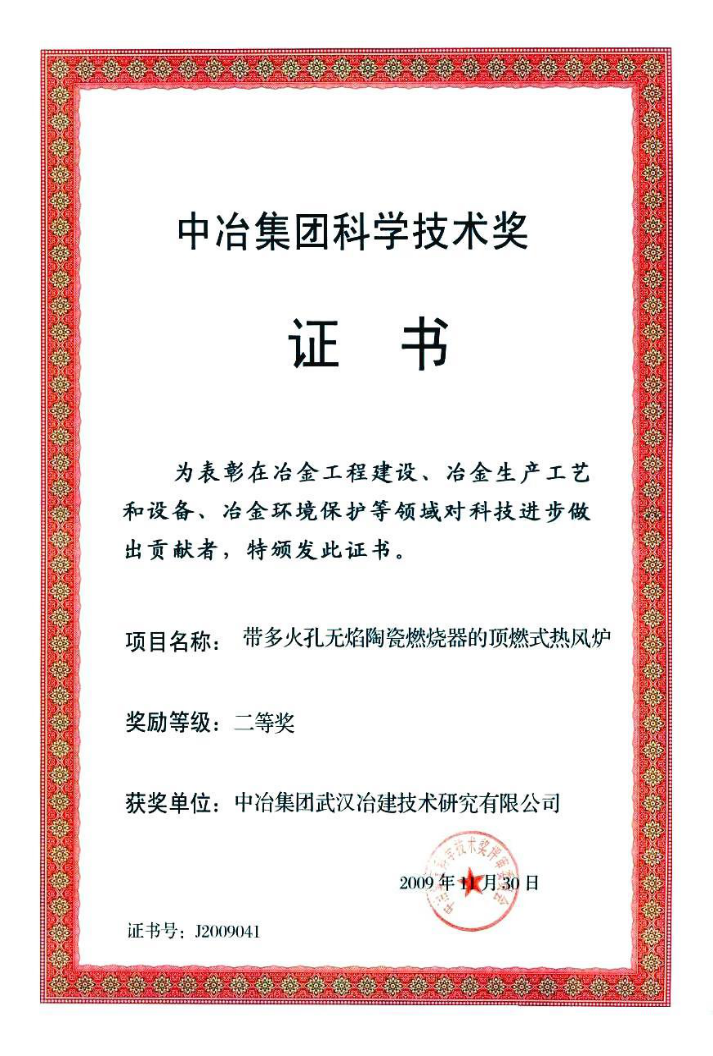

The continuous development of blast furnace ironmaking technology requires that the wind temperature of the hot blast stove is gradually increased, resulting in serious damage to the furnace body and its piping system, and the life expectancy is significantly reduced. Through research on the piping system structure and refractory materials, the project has developed the longevity technology of hot blast stove, the uniform gas distribution technology of hot blast stove, the ceramic burner technology of hot blast stove and the heat maintenance technology of hot blast stove.

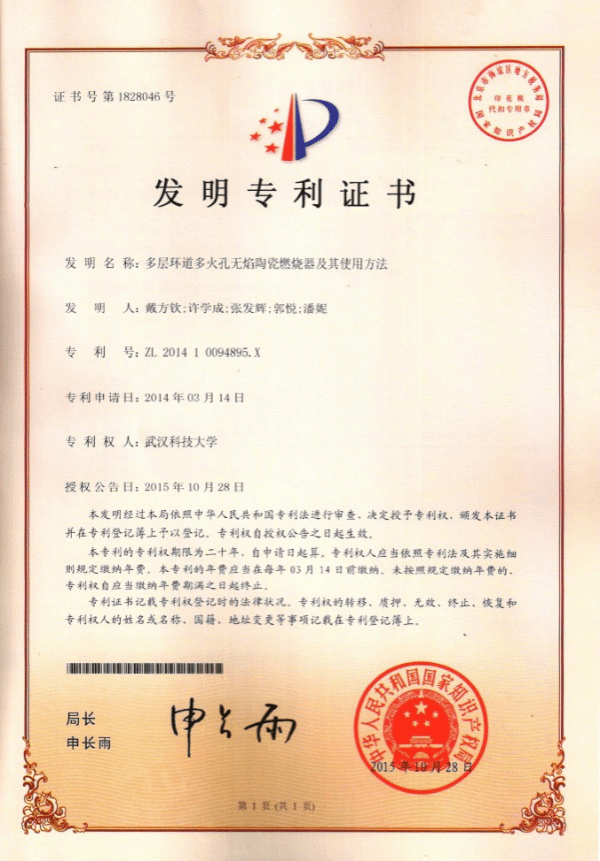

The technology was developed by Professor Dai Fangqin. Professor Dai Fangqin began research on hot blast stove technology in the late 1990s. He presided over the design of the blast furnace hot blast stove of Taiyuan Iron and Steel Company, the blast furnace hot blast stove of Xinyu Iron and Steel Company, and the hot blast stove of No. 1 blast furnace of Egang. The contracting project, the renovation of the top-fired hot blast stove of Rizhao Iron and Steel Co., the design of Hengyang Hualing blast furnace hot blast stove, the design and general contracting of the hot blast stove of Fujian Yixin Iron and Steel Co., Ltd. The technology is now responsible for engineering transformation and implementation by Wuhan Keda Zhongda Engineering Technology Co., Ltd.